Industrial processes that require very high temperatures are particularly under scrutiny in terms of CO2 reduction and cost savings. High-costs, growing environmental regulations, and the desire for resource conservation all require action.

The production economy is challenged to use energy extremely efficiently, reduce CO2 emissions, and use all possible means of energy recovery. In addition, a profitable and stable plant operation depends on a safe and economical power supply.

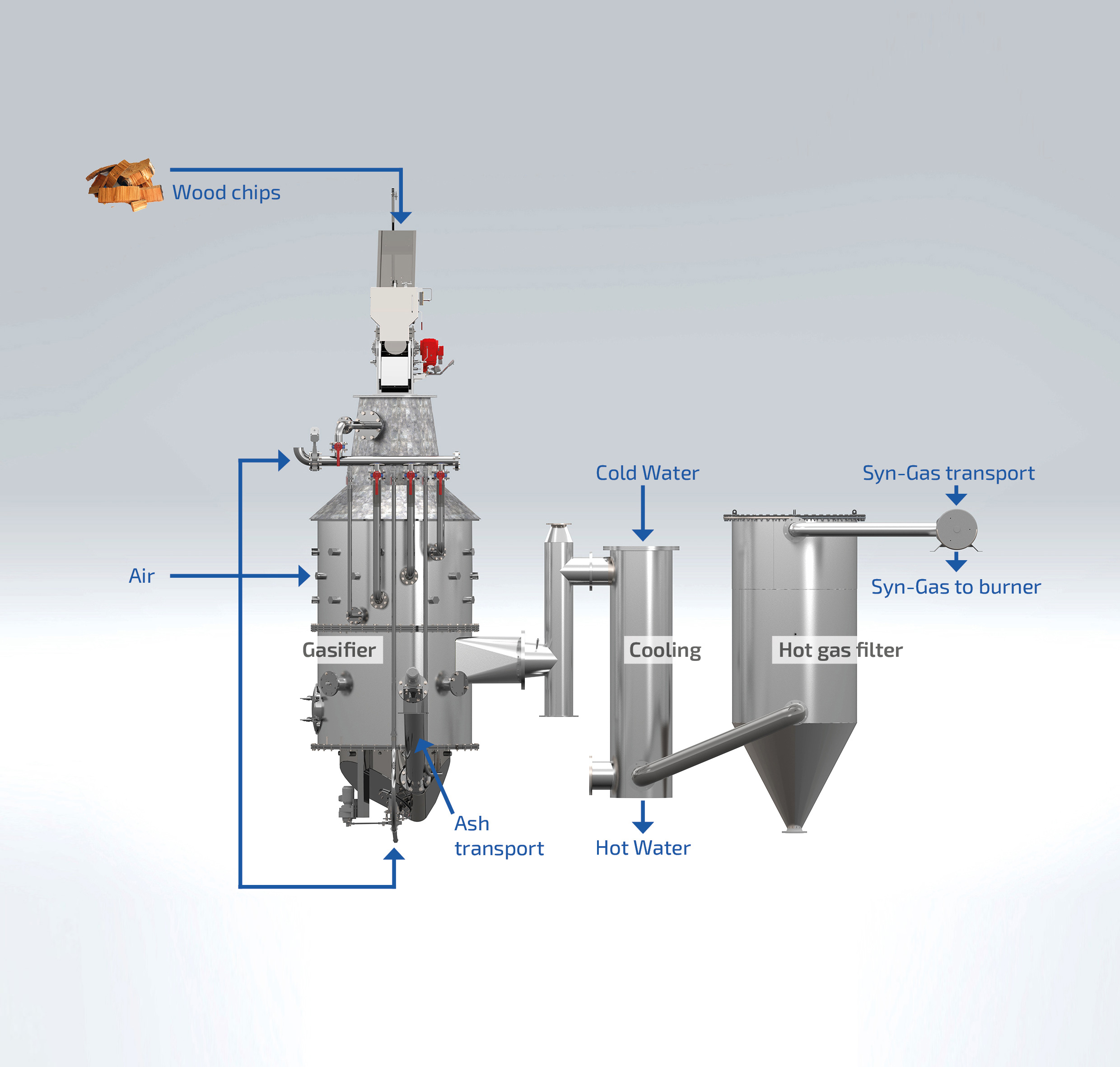

In the context of stricter emission regulations and the use of CO2-neutral feedstocks, the concept of AHT synthesis gas plants is a perfect alternative to conventional heating concepts and furnaces based solely on combustion, especially when it comes to high temperatures.

Existing systems, particularly those based on fossil fuels such as natural gas, can be easily converted to synthesis gas. Much of the infrastructure can be reused, thus sensibly extending the remaining service life of existing investments.

The synthesis gas produced from renewable feedstocks can be used either as raw gas or as processed and cooled gas, and simply applied in high-temperature processes requiring more than 400°C.

Use of synthesis gas in high-temperature processes

Many industrial processes that require high process temperatures can be converted and operated with CO2-neutral feedstocks.

Your advantages: |

|---|

|

|

|

|

|

Usage of Raw Gas

In general, raw gas can be used for all applications in which heat is the primary requirement and gas quality is secondary. Many industrial processes can be converted and operated with CO2-neutral feedstocks. Application examples can be found especially in heavy industry as well as in building technology.

Example Heavy Industry | Example Building Technology |

|---|---|

|

|