The generation of gas from renewable biomass is ideal for independent and decentralized concepts for providing hot gas, heat, and electricity, offering a high degree of independence from fossil fuels.

Within the AHT biomass power plants in the range of 0.2 to 10 MW, our efficient Twin-fire gas generators provide for the thermochemical conversion of the input materials and generate usable synthesis gas from a variety of renewable raw materials or biogenic residues. By combining ascending and descending gas production, the Twin-fire gasifier creates the basis for a very clean process gas even before the gas cleaning process.

AHT Twin-fire gas generators can process not only various types of wood – including treated wood – but also other input materials such as fermentation residues, sewage sludge, or manure. In our flexible process, the process is adapted to the input material. Gas can be obtained from liquid input materials through preparation such as HTC/VTC for further use.

If you have access to biogenic residues, we are happy to test their suitability – this can significantly reduce overall costs. For example, our systems can generate around 14 GW of electrical energy and 16 GW of thermal energy from 10,000 tons of waste wood, with the proportions also being modifiable.

Functionality

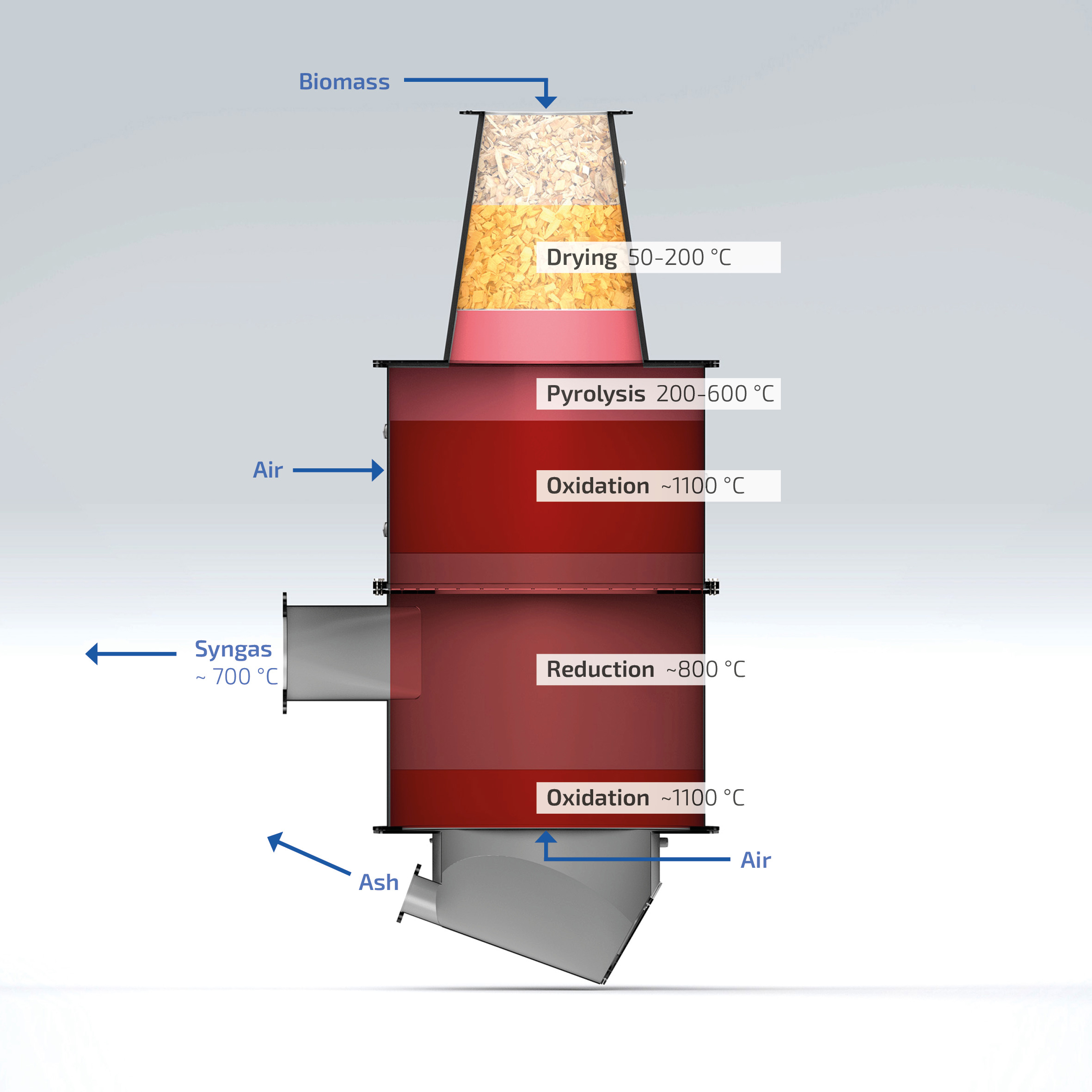

The biomass pre-conditioned for gas production is fed to the gas generator from above. Feeding is automatic and controlled by the level of the input material in the conical part of the gas generator. The input material is optionally dried and pyrolyzed.

The AHT Twin-fire reactor operates with the advantages of updraft and downdraft gas production in two oxidation zones. Decomposition reactions take place with controlled addition of oxygen from the surrounding air, converting the hydrocarbon compounds of the biomass into combustible process gas. The gas leaves the gas generator in the middle section, where it is sucked out by negative pressure. The residual ash is automatically discharged through an ash grate and a conveyor screw in the lower area and fed to the subsequent process steps. We are happy to check on a case-by-case basis whether profitable reuse of the ash is possible.

From Biomass to Syngas

The AHT Twin-fire reactor operates with the advantages of updraft and downdraft gas production in two oxidation zones!

Advantages & Effects

|

|

|

|

|

|

|

|

Existing systems can be supplemented by our technology – the AHT gas generator can easily be integrated into the existing infrastructure of a biogas or sewage treatment plant or used in existing burner systems.